Demystifying the World of Flanges: Types, Applications, and Selection Considerations

Get in touch !

- Dubai, UAE

- No Comments

Introduction

Significance of Industrial Flanges

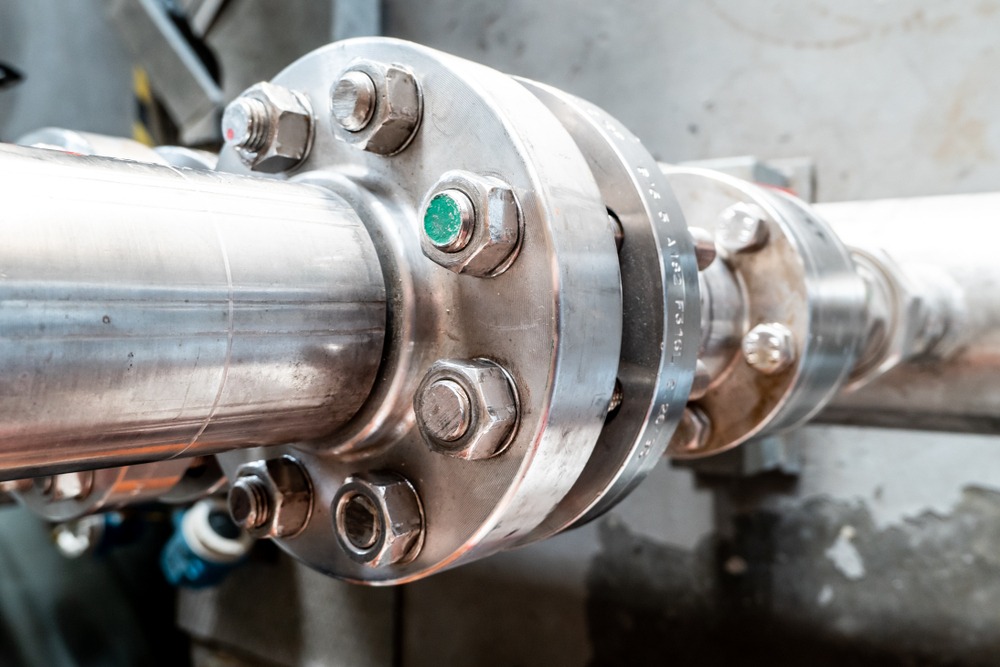

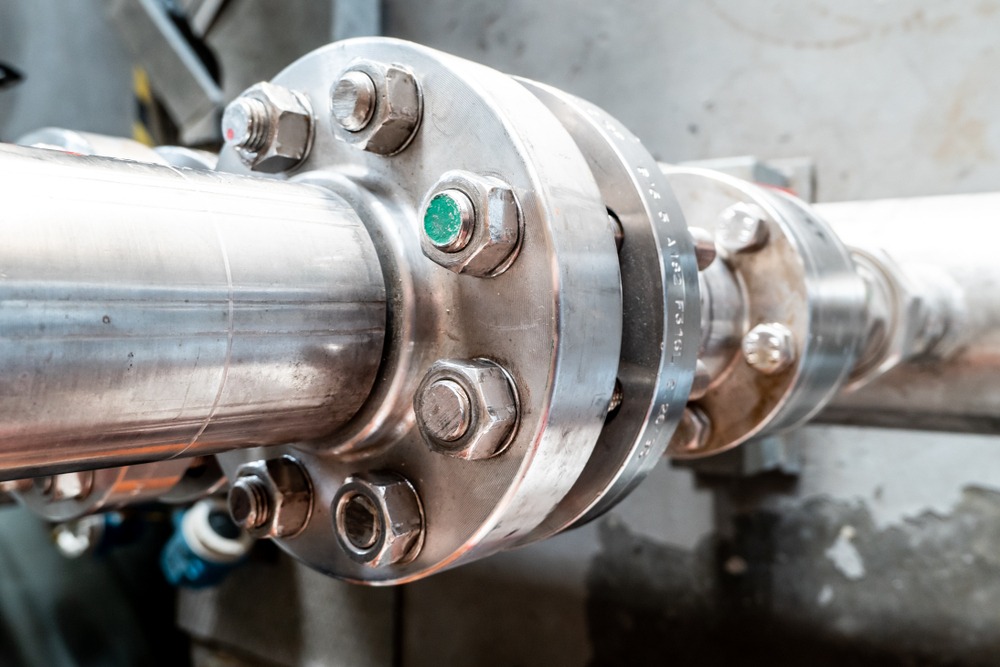

Industrial flanges serve as essential connectors in pipeline systems, facilitating the seamless flow of fluids, gases, and materials in various industrial processes. From oil and gas to chemical processing, water treatment, and beyond, flanges play a vital role in ensuring the integrity and reliability of critical infrastructure. Whether it’s joining pipes of different materials, accommodating thermal expansion, or providing access for maintenance and inspection, flanges are integral to the efficient operation of pipeline systems.

Applications of Engineering Flanges

- Oil and Gas: Used in pipelines, refineries, and offshore platforms for transporting crude oil, natural gas, and petroleum products.

- Chemical Processing: Essential for handling corrosive chemicals, acids, and caustic substances in chemical plants and manufacturing facilities.

- Water Treatment: Employed in water distribution networks, sewage treatment plants, and desalination facilities for conveying potable water and wastewater.

- Power Generation: Utilized in power plants, steam turbines, and nuclear facilities for transporting steam, coolant, and other fluids in energy generation processes.

Importance of Pipeline Components

Conclusion

Industrial flanges are essential components in modern engineering, playing a vital role in the seamless operation of pipeline systems across various industries. By understanding their significance, applications, and the importance of selecting the right components, you can ensure the integrity, reliability, and efficiency of your projects. Explore the comprehensive range of engineering flanges available at MBTC UAE and elevate your pipeline systems to new heights of performance and reliability.

Get In touch

Steel fabrications